Stedin accelerates energy transition with emission-free and ergonomic innovations

Challenge

Accelerating the construction of low- and medium-voltage grids, with a special focus on zero-emission and ergonomics.

Results

With tech and sector scouting (open innovation), solutions were sought for each bottleneck, resulting in no less than 211 solutions for zero emission and 187 ideas for ergonomic improvements. Three strategies were then developed for zero-emission and ergonomics, with a clear focus on practical and feasible implementation.

Client

Stedin: A major grid operator in the Netherlands responsible for over 2.3 million households and business customers

In short

Stedin wants to accelerate the energy transition and scale up the construction of electricity grids by deploying zero emission and ergonomic innovations. The aim is to scale up construction by carrying out work emission-free without CO2, nitrogen or particulates, and with less physical strain for mechanics. nlmtd was engaged to explore innovative solutions worldwide using databases, experts and insights from other sectors. The approach resulted in scenarios that accelerate grid construction precisely because they contribute to sustainable construction and (physically) more inclusive working conditions.

By investing in zero emission and ergonomic solutions, Stedin is not only contributing to the energy transition, but also to a healthier planet and healthier working conditions.

- Daisy Rood (nlmtd)

Challenge

Emission-free scale-up

The energy transition requires a drastic scaling-up of electricity grids. When building grids, emissions are a limiting factor (especially in Natura 2000 areas and emission-free zones in cities). The use of diesel engines, for instance, causes nuisance and increasingly leads to delays or even postponement of projects. Stedin is looking for solutions for emission-free construction.

Reducing physical strain

In grid construction, staff availability is another limiting factor. The work of mechanics is physically demanding due to heavier cables and crowding above and below ground. Stedin wants to make the profession more attractive and inclusive by reducing the physical load for mechanics. With smart innovations, Stedin can lead the way in ergonomic improvements.

We wanted to make sure with this reserach that we looked at all options to accelerate. That we are not overlooking any ready-made solutions.

- Trudy Onland (COO bij Stedin)

Process

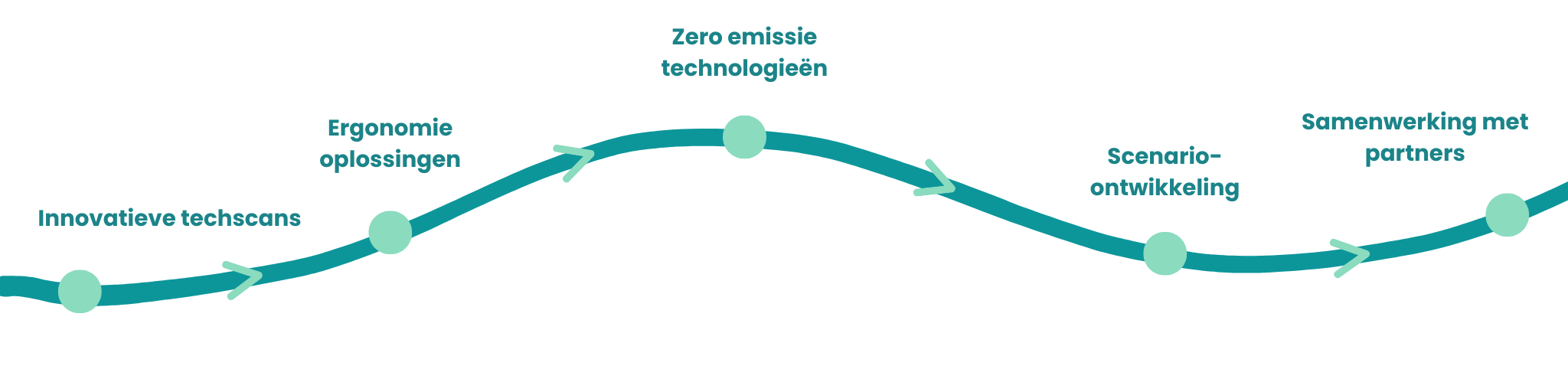

nlmtd was asked to help think about these challenges. The main question from Stedin: ‘Are we not overlooking smart solutions (inland and abroad, or other sectors) that could help us?’ We started working on this question through an intensive search for solutions, using tech scans, workshops, field visits and expert sessions. From this, relevant technologies emerged that were tested based on scenarios, after which they could be implemented in cooperation with partners.

Deepdive in the process

Innovative tech scans

The approach was to analyse current challenges and look for innovative solutions. This was done using a ‘watchtower’ project, in which we searched for innovative solutions globally in three ways.

- We scout databases for tech solutions.

- We launch challenges.

- We do research and consult experts from other sectors and at home and abroad.

In this way, the ‘watchtower’ provided new insight into various available solution directions and identified relevant technologies in both emission-free construction and reducing physical load during grid construction. See here the infographic about zero-emission and ergonomics.

For example, we spoke to a participant in the Volvo Ocean Race about how she makes sure she functions optimally while performing highly physical work in difficult weather conditions.

- Nick Mastenbroek (nlmtd)

Scenario development

The ‘watchtower’ project also helped identify end-users, their activities and needs. In addition, the main problem areas, trends, developments and existing initiatives around emission-free and ergonomic working inside and outside Stedin became clear. These were all valuable insights that helped in the development and selection of promising scenarios. The scenarios gave an important insight into the usability and feasibility of the solutions found.

Cooperation with partners

Valuable solutions soon emerged. This is a positive outcome for Stedin and Netbeheer Nederland, with which they can start working immediately. To implement the emission-free solutions, they collaborated with several partners such as Emission-0, an online platform for renting and leasing electrical equipment for construction work, and Limach, a manufacturer of electrical construction machinery. For the ergonomics issue, partners included AirSpades, a manufacturer of air-powered soil excavation tools, Nano-drills, a very compact drill for laying relatively short pipes and cables, and sensor technologies to reduce physical strain and promote inclusion.

Results

We ended up with 211 zero emission solutions and 187 ergonomics solutions. Both were categorised and prioritised. For zero emission construction, we saw in particular solutions for sustainable digging, sustainable transport and making power sources more sustainable. To improve ergonomics, we particularly saw solutions on mechanisation, ergonomic tools and material and prevention. The solutions found are shown in an infographic.

Meanwhile, electrification of construction equipment has started through partners, ergonomic tools such as AirSpades and StrongArm harnesses are being implemented and a knowledge platform is also being activated to share innovation.

Next steps

Collaboration and urgency have proved essential in this journey. Now that the solution directions have been worked out, the focus is on scaling up successful pilots (‘the gearbox’) and distributing actions within the ecosystem. Under the guidance of nlmtd, this process was shaped, focusing on questions such as ‘who picks it up?’ and ‘how does it work?’. Stedin is funding ‘the watchtower’ and has shared the results widely with an ecosystem that includes contractors, grid operators and other stakeholders. By sharing knowledge and working together, maximum impact is realised.

Conclusion

Stedin has proven that a sustainable energy transition is within reach when innovation and collaboration are the driving forces. By focusing on zero emissions and ergonomics, Stedin combines environmentally responsible solutions with a focus on employee health and inclusiveness. This integrated approach shows that progress in sustainability can go hand in hand with improved working conditions and social responsibility, setting a powerful example for the sector and beyond.