EemsEnergyTerminal at Eemshaven from good to better

Challenge

The LNG terminal in Eemshaven was completed in just six months, a speedy turnaround. This is inspiring, but also offers room for further optimization. In short: how do we go from good to better?

Results

The goal was Stable Operational Excellence – stable processes with a focus on efficiency, quality, and continuity. The improvements brought more structure, optimized processes, more precise work instructions and roles, and improved IT systems. Always with the starting point: customer, environment, terminal, and ourselves.

Client

EemsEnergyTerminal in Eemshaven is a floating LNG terminal, necessary for energy security and to reduce dependence on Russian natural gas. EemsEnergyTerminal is a subsidiary of Gasunie and Vopak.

In brief

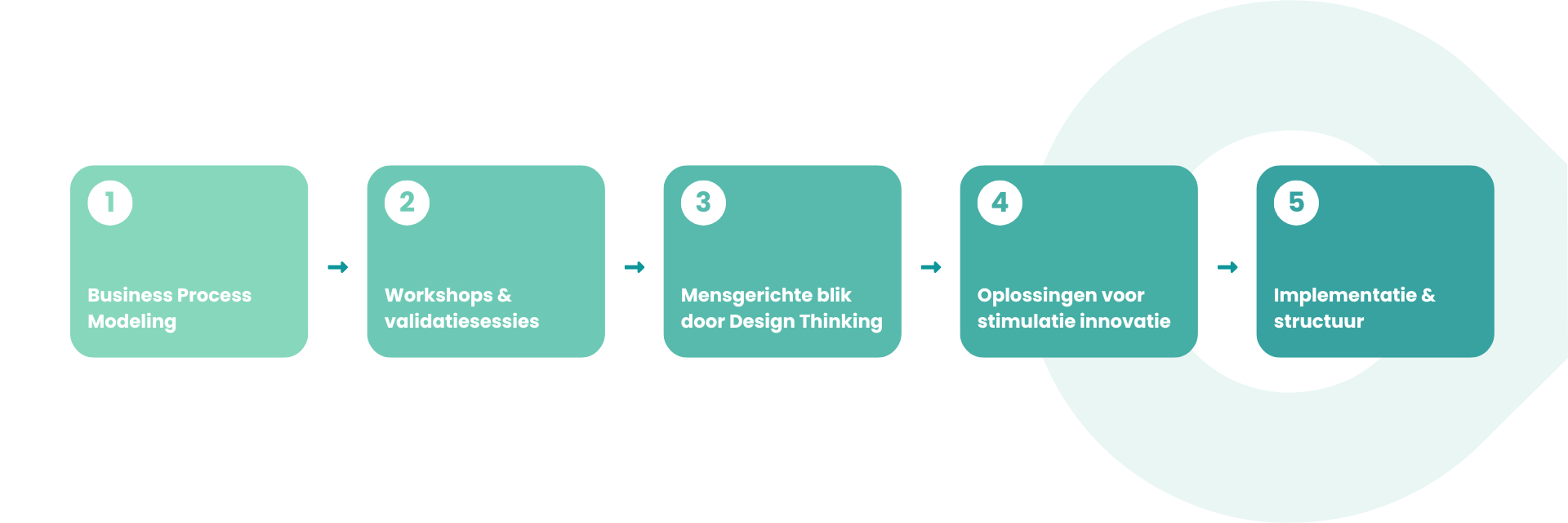

The LNG terminal opened in September 2022 and was completed in about six months. This is short, so there was room for improvement. nlmtd was asked to make that improvement. Using Business Process Modeling in combination with workshops and validation sessions, we began creating a future-proof organization.

A stable foundation in our processes is essential. Doing so not only builds reliability and efficiency today but also creates the basis for a sustainable future.

- Daphne Schipper (nlmtd)

The LNG terminal at Eemshaven

Facts & figures

The LNG terminal in Eemshaven is a facility for importing, storing, and regasifying Liquefied Natural Gas (LNG). This is done before the gas enters the Dutch and European gas network. This is necessary for energy security in the Netherlands and Western Europe, and helps reduce dependence on Russian gas.

- Opened in September 2022 in response to the energy crisis and reduced gas supplies from Russia.

- Has a capacity of 8 billion cubic meters of gas per year (about 25% of the Netherlands’ gas needs).

From 1 to 600 liters

The terminal consists of two floating storage and regasification units (FSRUs). From an LNG carrier, liquid LNG is pumped to these floating storage and regasification units (FSRUs). Then the LNG, which is cooled to -162 °C to transport it as a liquid, is reheated, increasing its volume from 1 liter of liquid to about 600 liters of gas. The LNG is thus delivered in gaseous form to the Dutch gas transport network, where market participants trade it. Gasunie has realized an LNG import terminal through the implementation of an FSRU-based terminal in a short period.

Challenge

The LNG terminal opened in September 2022 and was completed in about 6 months. The short time frame is unique and inspiring, but there is always room for improvement. By comparison, other energy projects take between 3 and 5 years. To realize improvements, nlmtd has been brought in through Daphne Schipper, together with the EemsEnergyTerminalTeam. The goal is Stable Operational Excellence. In other words, stable execution of business processes, focused on efficiency, quality, and continuity.

Deepdive in the process

To ensure stable operation, Business Process Modeling was initiated alongside workshops and validation sessions. Thus, business processes were mapped visually, and optimization opportunities were highlighted. Design Thinking was used to identify people-centered, creative methods to address potential problems and stimulate innovation. Based on the insights, a targeted action plan was developed with clear deadlines, team meetings, and oranges with smiley faces: after all, with a smile, you achieve even better results.

Results

After the study, work began on implementing improvements. This resulted in more structure, optimized processes, valuable documents, and precise work instructions. In addition, roles and responsibilities have been more clearly defined, and IT systems have been significantly improved. Always with the starting point: the customer, the environment, the terminal, and ourselves.

A stable foundation is crucial for a green future.

- Daphne Schippers (nlmtd)

Next steps

Currently, the LNG terminal imports Liquefied Natural Gas (LNG) and converts it into gaseous natural gas for distribution in the national gas network. Gasunie and Vopak are currently investigating the extension of the EemsEnergyTerminal. They are also jointly investigating the feasibility of establishing a hydrogen import terminal and developing a CO2 transport hub at Eemshaven. The terminal remains crucial. And that is why we have gone from good to better.

Conclusion

With pride, Daphne and the EemsEnergyTerminal team look back on the first improvements and forward with equal ambition. The first milestones have been reached, and in 2025, we will take the next step towards a future-proof terminal!